金型設計/製作MOLD DESIGN/PRODUCTION

TAITO’s acquisition and application of CAE / CAD / CAM technologies

Taito’s metal stamping division believes “Die tooling is the core technology for the metal stamping operation” and has manufactured 100% of our Dies inside our facilities for 20 years since its foundation is always working continuously to further new technologies.

We have manufactured Dies with the belief that “what is most important is Die tooling” in the production with the metal stamping operation.

We deal with the whole process from designing to processing and assembly consistently inside our facilities and almost 100% of Dies used for production processing are manufactured within the company.

We have also increased accuracy, stiffness and shortened delivery time of Dies in order to make highly difficult metal stamping operation possible at an early stage.

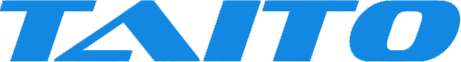

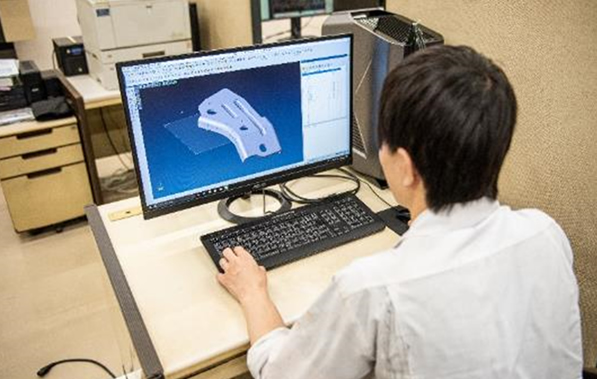

CAD / CAM / CAE analysis

Taito conducts work meetings at every order of components and makes various propositions to make high-volume production seeking higher quality reliability possible by gathering skills that we have such as VE proposition to a customer, yield improvement proposition and manufacturing-friendly proposition.

The whole designing

2D CAD

3D CAD

CAE analysis

Precision Metal Stamping(Machining process, wire cut process)

Aiming at realizing higher accuracy, Taito conducts micro processing to conduct direct milling of our die material(suitable HRC 60)by Yasuda and Ohkuma horizontal pattern machining center.

For Die set, we also aim at realizing high accuracy with accuracy verification by in-process measuring after processing. Regarding wire-cut processing, we pursue increased accuracy of components dealing with temperature management, heat shield and measures against vibration and higher accuracy by shape measuring with a high-accuracy measuring machine.

The whole MC

CNC jig borer

The whole WC equipment

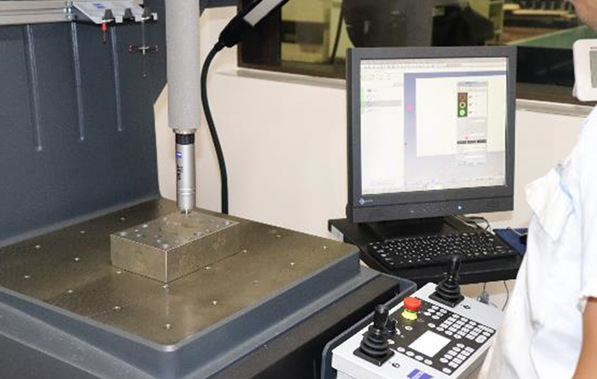

Three-dimensional coordinate measuring machine

Three-dimensional measurement

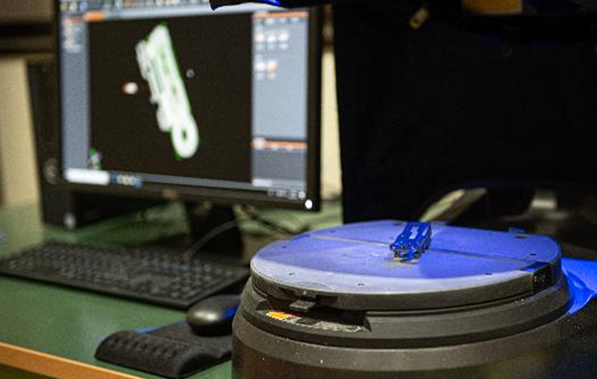

We’ve implemented improvement by checking relations between the Dies and a product while observing the Dies to be measured and measuring a product.

SD scanner mold, three-dimensional measuring machine

Others:Profile(Profile grinding)

For a complex profile, we ‘ve achieved polishing work on complicated-formed punches by the use of two WASHINO-made profiles in order to increase accuracy and durability of punches.